Rumi

Caravan Tiny Travel Trailer

Designed and built by: Henry Benner,

July 14, 2010

Copyright © 2010,

Henry Benner, All Rights Reserved

eMail:

[email protected]

Last updated: September 7, 2011

THIS

PROJECT BEGAN ONE DAY when I realized that my gas guzzling Chevy truck

and camper was just too expensive for the environment. So I bought a

small

fuel-efficient car and scrapped the truck and camper. This trailer is

the replacement for the camper.

The

trailer provides a comfortable bed (double) in a wind-tight and

insulated shell; plentiful and convenient storage, a toilet, a

desk/table, a mini kitchen with single burner propane stove, sink,

insulated water jug, electric

heater, and an alcohol heater.

It works well in conjunction with a portable gazebo and regular camping

equipment.

It weighs only 415 pounds (189 kg) so it can be towed by a

small car. If you build it yourself it will probably cost less than

$1500 USD.

It

also doubles as a utility trailer; wide enough to transport 4x8 sheets or items too large or awkward for the car. (The entire

rear panel is removable.)

Like my old truck camper, the trailer

is very convenient for traveling–there is nothing to setup and it's

completely self-contained so no campground is required. On a long trip

just park overnight on a quiet street, on vacant land, or at a rest

stop.

This website describes the construction of the outer shell.

Specifications

| Overall width (excluding

fenders) |

53 inches |

| Overall length (excluding

drawbar, with drawbar) |

130, 158 inches |

| Interior width |

50 inches |

| Interior floor length |

120 inches |

| Exterior height |

73 inches |

| Interior height (highest,

lowest) |

56, 42.5 inches |

| Weight (with hitch jack, without jack) |

415, 400 pounds |

| Cost to build (trailer,

shell materials) |

~$1200 ($560, $620) |

| Windows, door hinge |

from an old truck camper |

| Trailer, lightweight

tubular |

Snowbear

480K, minor

modifications |

Estimated time to build

(excluding trailer assembly, aquiring materials, or

painting) |

45 hours |

Construction Details

Drawings (click on

links)

Technical

Drawing of Framing

Double

Bed Floor Plan

Single

Bed Floor Plan

Walls

The walls are bolted directly to the sides of the trailer

frame and are hollow construction throughout.

A

simple method to build the wall frame is by using a construction panel.

This allows you to work vertically and eliminates tricky

clamping.

To build the construction panel join

sheets of OSB or plywood together with metal roof truss plates and

cut it to the outer shape of the trailer. Paint both sides white

(optional). Support the panel vertically.

Draw your plans directly on the construction panel. The panel in

the photo was the plywood wall from a prototype

trailer.

Framing

members are either 1½”, 2½”, or 3½” wide, all ¾" thick--installed

on the flat. Standard lumber sizes

(1x2, 1x3, 1x4) could be used but it's better to buy the best

quality stock, regardless of width and/or length, and rip the required

sizes with a table saw. Use pieces that are as clear as possible

(knot-free).

Frame in the door, windows, and fender supports. Add lots of

structural strength where the walls bolt to the trailer

frame. The bottom of the frame is level with the top of the axle so a

cutout will eventually be required to allow for axle movement.

Screw

the framing

members to the construction panel with small screws. Don't be too

concerned if your joints are not tight--the glue will bridge small

gaps. When you have finalized the structure place some wax paper

between each joint and the construction panel, then glue and

gusset each piece in

place.

A very good glue for this application is a

Polyurethane

Construction Adhesive such as LePages PL Premium

or

equivalent. This glue bonds to wood, metal, plastic and is perfect for this

application–having excellent adhesion and remaining flexible.

Use

gussets on each joint for added strength. These are small strips of

thin metal roof flashing stapled or nailed over each freshly glued

joint–let the

glue squeeze out from under the gusset. (To ensure glue will stick to

metal clean it with thinner and roughen with emery

cloth or sand

paper before cutting into strips.)

Wipe off excess glue with a rag

and

paint thinner.

After the glue dries trim frame to the curve with a

jigsaw

(or,

before gluing, trace the curve onto each segment piece, remove

from panel, cut with bandsaw).

When glue has cured sufficiently remove frame

from the construction panel and install the backside gussets with glue

and staples or brads.

The

final result is amazingly strong. Framing members can also be easily

added or removed.

Using a 1x6 board along the bottom instead of a 1x3 simplifies

construction but adds unnecessary weight.

Reverse the construction panel to build the other wall.

Trailer Notes:

- The

trailer in the photo above is a Snowbear 480K. It's a

standard 4

foot by 8 foot utility trailer (bolt-together kit) with a lightweight (200

lb) tubular frame. The supplied 8 inch wheels were replaced with 12

inch ones. The

drawbar was relocated 12

inches forward for better weight distribution.

- Some

wood crosspieces and extensions were added for extra floor support and

to accommodate the rear panel.

- Trailers that have

the axle located 60/40 (40% from the rear) are just about right.

Hitch weight should be 10%-15% of

gross trailer weight for

proper towing. And backing up is easier when the axle is located towards the rear.

- Almost

any lightweight

trailer will serve. Check out canoe trailers or other boat trailers.

- For a low deck get a trailer with the springs slung under

the axle.

- Shock absorbers would be beneficial.

Roof Spars

The

roof spars are fabricated from clear spruce lumber 2½”

wide by

¾” thick by approximately 50” long (measure to get

the exact length). At each end a right-angle furniture bracket

(Stanley 08-8894) was attached with machine screws. Put some carpenters

glue on the threads at final installation.

Install

the first and last spars at the ends. Then locate the remainder

approximately 16” center to center. Consider where the crown roof skin

will be located before finalizing the location of the spars. Locate

another

spar over rear panel framing. Refer to the drawing. Photo is of a

plywood prototype, this trailer uses the same technique for the spars.

Install triangular blocks at the rear in the

corners of roof spar and side frame to support the tail lights and to

add stiffening (or use a metal right-angle bracket if lights are going

to be mounted outboard).

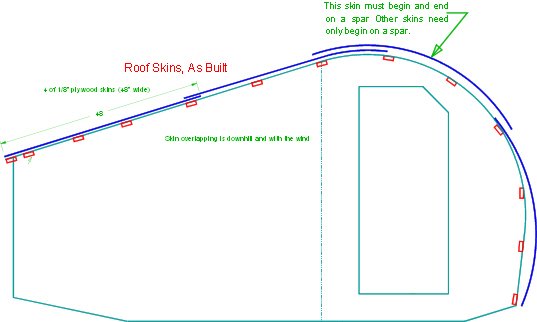

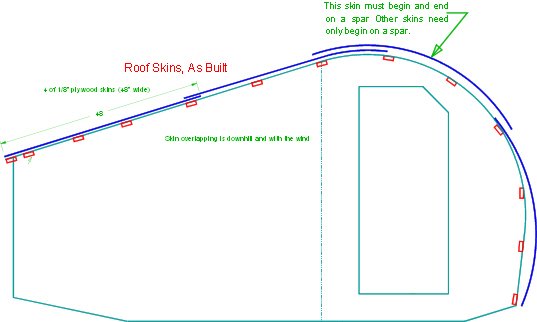

Roof Skins

Roof skins are ⅛” marine plywood.

Skins overlap each other and overhang the outside walls approximately ¼

inch. Double up the thickness

at the rear of trailer by adding an 8” strip of thin plywood. Apply a

bead of caulking along the roof spars,

roof edges, and on overlaps. Use ratcheting tie downs lengthwise over

the roof to hold the

curved skins in place while fastening. If necessary dampen

skins with water before bending. (Laying skins on wet lawn works well.)

Fasten with #9 roof screws

(every 8 inches). Be sure to install screws at right-angles to the

surface or the rubber gaskets will not seat properly.

Insulate

the inside of the roof and curve with single-sided foil radiant barrier insulation.

The

foil faces the empty

cavity between the spars (foil needs a minimum 5/8" air-tight space to

be effective). This will provide R-5 insulating value as

well as providing a good radiant barrier (i.e. acts like a heat

reflector). Support the wrap on the spars

with strips of ⅛” plywood or double-sided tape and caulk or tape along the edges to make it air-tight.

Door, Floor, Rear Panel, and Trim

Examine

a standard house exterior door

to get door frame and construction details (bear in mind that the

trailer

door opens outwards; plus, allow for a screen door mounted inside the

trailer door). Install a door sill and slant it forward so

that rain does not run inside. Use standard

door weather stripping and

lockset. Use a piano hinge if you can find one

that’s made for exterior use (from an old camper for example).

Install ⅜” OSB floor and baseboards as required. Seal

any gaps with expanding foam or Gorilla® tape. Most campsites have

power outlets on the road side of trailer sites so install a power bar

or power cord through the floor at the front on the road side.

Here's

an alternate light-weight floor idea: Stretch and fasten light steel

mesh across the frame of the trailer. (Some stores refer to this mesh

as Hardware Cloth.) Cover

with 2' squares of interlocking garage floor pads. These pads are made

of light but tough foam. I've seen them at Walmart in the automotive

department. Unfortuately I haven't had a chance to try this out

yet...so you're on your own here. This would probably save 10 to 15

pounds over an OSB floor.

Install

exterior panels (⅛”, or ¼” plywood) with #5 or #6 roundhead

screws (spray painted white) every 16 inches and around the door frame.

Fill cracks or gaps with white paintable caulking. Install the

windows.

Build

the rear panel. Panel is bolted to the back with four #10 or ¼

inch bolts

and shakeproof hardware. Install a gasket or weather stripping to seal

it.

Tail

lights are attached to blocks

screwed into the corners of the wall and roof structure members. This

allows the trailer to be used as a utility trailer without the rear

panel in place. Or, mount the lights on the outside of the walls with

brackets. Don't forget to run a ground wire to each light.

Install ¾”x¼” spruce trim along bottom edge of exterior panels

to protect fragile edges. Install similar trim at rear to hide details.

Install sheet metal strips on bottom of framing where rear of

trailer could drag on steep driveways.

Fenders

Fenders are fabricated from two layers of ⅛”

skins. Pop-rivet one layer to four equally spaced metal strips (e.g.

brick ties) that have been bent into an ‘L’ shape and drilled. Bend the

fender into the shape you want and fasten to a piece of scrap plywood

to hold that shape. Then glue and clamp the second layer on top of the

first layer–hiding the pop-rivet heads. Coat the inside with black

roofing compound to waterproof it. Mount fenders offset from the

trailer wall with thin wood or plastic spacers and #10 machine

screws.

Finishing

Paint it; add colorful trim or decals; install lights and

you’re done!

Misc Notes

- To make it possible for this trailer to be towed by a low powered

car the design

was inspired by typical sailboat shapes...these are generally long and

narrow. Increasing

the width or height might adversely affect the roadworthiness

to the point where it's no fun towing it...especially into a head wind.

If you have any doubts regarding the ability of your towing vehicle it

might be advantageous to build a simple plywood prototype. This could

be as simple as a 'post and beam' style of construction (simply bolt

some 2x4's to the trailer frame and cover with plywood), then take

it for a ride under windy conditions.

- Towing was very easy with my small car (2007 Suzuki SX4, 2L,

143hp, 5-speed manual transmission) with more than enough power. The narrow

shape is great--no extra mirrors required.

Fuel-efficiency was reduced by about 26% (from 34

mpg

to 25 mpg, US

gallons). Little side movement in cross-winds. More about

aerodynamics here.

- If

you don't have much experience with woodworking, don't have a shop, or

are pressed for time try using the Alternate

Construction Method (see the next section).

- If you don't own a table saw it might be worthwhile to

purchase

one. The one used in this project was a hardware store "house brand"

costing less than $100. A mitre saw is

also very useful--again, under $100. If you are going to borrow a

friends table or mitre saw, offer to buy and use your own blades.

- Metal skins would be more durable; have trailer

painted at an autobody shop or leave it natural.

- Why the name Rumi

Caravan? Well, I love the poetry of sufi Mevlana

Jalaluddin Rumi, especially this one:

Come, come,

whoever you are.

Wanderer,

worshipper, lover of leaving.

Ours is not a

caravan of despair.

Come, even if you

have broken your vows a thousand times.

Come, yet again,

come, come.

- To honor Rumi and experience maximum creativity and

enjoyment from each step of the project, build it practicing inner stillness.

- Don't

get caught up in making it very fancy, after all, it's a

camping

trailer. Fancy woodwork and paint jobs are great but soon get scratched

and damaged. It won't be professional

looking,

but then again, you probably don't have access to the shop and tools

that professionals use. Make it your work of art--where "imperfections"

are part of the appeal (like the difference between a painting and a

photograph).

- What makes this trailer better

than a store-bought unit are all the little goodies

you add later--the hooks in just the right places, the LED

lights,

the shelves and drawers custom made for your stuff, the cute icons and

decals that make it quintessentially you.

- The

reason for the copyright is to prevent anyone from falsely claiming

ownership of the design or website. You are free to use this

information, but I'd appreciate credit if you refer to this material

(or just provide a link to this site).

- If

you plan to finish the inside, it will probably be easiest to build

from the inside out (i.e. install interior panelling and insulation

before installing the exterior skins).

Alternate Construction Method

This method was used to create the prototype trailer:

- Use standard exterior G1S solid plywood walls and doors.

- Use strap hinges on the doors--with foam

weatherstripping to seal it.

- Bed, table, seat, etc. are built-in and attached to the

walls for simplicity (optional).

Some pros, cons, tips regarding this method:

- Much faster to build, approximately half the time.

- Possible

to build without a shop, just space to store tools

and

materials, and a rain/sun

shade. Must be warm enough though--above 50 deg F overnight for proper

drying and curing. (One of my favorites: setup in a corner of the

parking lot at Home Depot or Lowe's, run in to buy material or rent

tools as you need them; even better if there is a Burger King or

Wendy's close at hand, and a movie theater too for afternoon

breaks.)

- Use acrylic paintable caulk instead of glue for fast

assembly.

- Windows or access doors/compartments can be installed at any time--even after unit is

built.

- No construction panel required.

- Plywood doors tend to warp, use a stiffener or fabricate a

standard thick door with frame.

- Much heavier, approximately 100 pounds more (for ½"

plywood).

- Plywood tends to crumble and/or separate with moisture and

vibration--marine plywood would be a better choice.

- Walls may need to be built up where spars,

windows, fenders, and

other structural items are fastened.

- Walls

are not insulated and will sweat

in cool weather or on cool nights--keep bedding away

from walls. Ceiling and curve can still be insulated. Floor could be

insulated. Fall/Winter/Spring camping will be limited.

- Walls are heavy and difficult to maneuver.

- Screws from the outside may protrude into the interior.

Ouch!

- Fastening to the edge of plywood is usually weak.

- Finishing the interior is simple--just paint!

- Built-in bed, desk, etc. detracts from usefulness as

utility trailer.

- More interior space (approx. 1" wider).

- Simpler tool requirements. Jig saw, drill, clamps, hand

tools.

- More difficult to make wind-tight unless a standard door and

frame is fabricated.

- When you're ready for The full Monty you can use the

walls as contruction panels for the hollow wall version.

More tiny travel trailer sites

Improvements

- For more storage space consider adding

long side boxes to replace the fenders. For the Snowbear

trailer they could be 16"H x 72"L x 7.5"D. These could be accessed from

the interior or exterior (or both) as desired. To improve aerodynamics consider 'skirting in' the wheel wells. The 'skirts' could be hinged at the top to double as small roadside tables.

- To strengthen and waterproof roof and curve consider a penetrating epoxy such as Rot Doctor.

- A wheeled swivel hitch jack is well worth the extra 15 pounds.

- A

curbside fold-down table or shelf is very handy.

- A

sliding rain/sun-shade mounted on the roof that pulls out over the

curb-side of the trailer. Could be as large as 54" x 80" to create a

sheltered space for sitting, cooking, etc.

- A fold-away awning/shade for the roadside window. It could be a framed solar panel.

- Small

light-weight 12 volt power pack. Charged from solar panel, car, or house. For powering

small appliances, music players, LED lights, etc. Lithium-ion batteries

are the lightest--get them from old laptop computers--usually only one

cell goes bad and the whole battery pack is thrown away. I've cut open

the battery packs and mixed and matched individual cells to get 12v and this works fine.

- A road-side slide-out to accommodate a side-ways bed. Also doubles as fold-up sofa. Dramatically increases 'living space'.

More Pictures

Interior

view. Shows the small desk/table, single burner propane canister stove

with heat shield. Used a folding army-style cot and 5" foamy on this trip. Lived with

this configuration for 6 weeks in the winter of 2010-11 on the desert near Las Vegas. A bit

cramped... trailer was not really designed for long stays... but it worked Ok once I adapted to the small space.

The planned new layout with side-slideout and folding couch/bed will

provide a lot more usable space.

Attending Northwest Sufi Camp

at Camp Adams near Mt. Hood, Oregon. Trailer is so light-weight it was

rolled into a sweet little shady alcove by hand. With the

prototype slide-out

awning and the fold-up side table. Leaving the back panel door

partially open makes for great flow-through ventilation (a screened

frame was

inserted in the opening). Hit a deer on the trip, hence the duct

tape to hold my car together. I've now accumulated more than 40K

miles on the little trailer, and have saved a pile of money on

accommodation. Plus it's great for travelling because you can take

long breaks during the hottest part of the day and drive in the morning

and

evening when it's cooler.

There's a lot of interest in these small trailers, so be prepared to give tours!

Free Camping Sites:

Free and almost free...